A legacy of growth: MAGNET marks 40 years of supporting NE Ohio makers

From its 1984 inception, Cleveland’s Manufacturing Growth Advocacy Network (MAGNET) has strived to be what president and CEO Ethan Karp calls “a good listener.” In practice, this means heeding the concerns of Northeast Ohio makers, while keeping abreast of the latest marketplace trends.

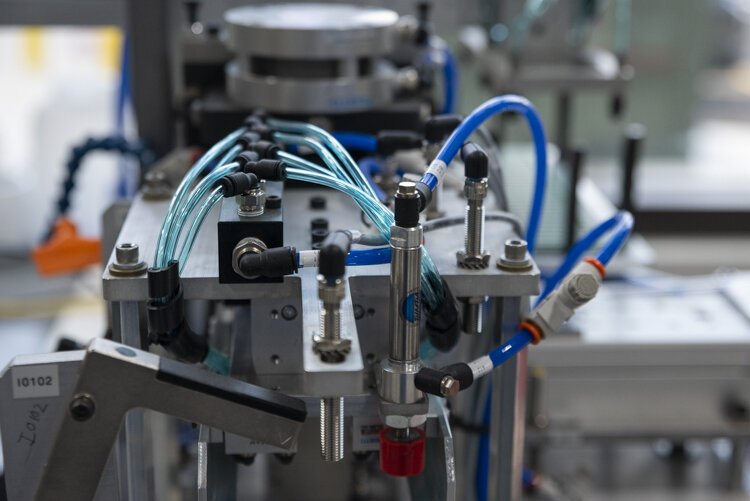

This mission has not changed in 40 years, even with dramatic shifts around technology and a larger understanding of what manufacturing can be. For starters, the image of manufacturing as “dark, dirty, and dangerous” no longer reflects the true state of the industry, Karp says.

Ethan Karp, president and CEO of MAGNET“In the early days, we were helping companies doing anything they could with computers,” he recalls. “Now, every machine has computers integrated into them, or AI buttons that detect errors and course correct [manufacturing processes]. That has improved quality, productivity, and even fundamentally reshaped the nature of the job.”

MAGNET launched as a pilot program for the federal Manufacturing Extension Partnership, which supported small and medium-sized producers through hands-on consulting and training. At the time, U.S. manufacturers were facing intense competition from Japan, whose products were both higher quality and more affordable.

From its origins in engineering support, MAGNET has expanded dramatically, now serving as a key resource for over 10,000 Northeast Ohio businesses in areas such as technology and leadership growth. As innovation fits hand-in-glove with manufacturing, MAGNET navigated companies toward new methodologies like lean production, which focused on minimizing waste and maximizing productivity.

The advocacy group facilitated the adoption of the early internet by regional builders, leading to quicker information gathering and streamlined inventory management. New product development required adoption of two important acronyms—CAD and CAM. CAD, or computer-aided design, uses software to create digital product models, while computer-aided manufacturing (CAM) helps automate those processes.

The rise of innovations including robotics and artificial intelligence has further transformed manufacturing, heralding the Industry 4.0 era of high-tech training and career opportunities.

“Now, it’s about data analytics, connecting your machines, and collaborative robots,” Karp says. “It’s an outgrowth of what we’ve already done, but now we’re deep into helping companies make these decisions.”

Shake it up

“Make It Better” forecasts a high-tech future that encompasses robotics, connected computing, enhanced automation, and other applications surrounding Industry 4.0A report released last March by MAGNET revealed that Northeast Ohio is fast becoming an advanced production hub. The organization’s first Blueprint Report Card—MAKE IT HAPPEN: A Progress Report on the Blueprint for Manufacturing in Northeast Ohio—also illuminated a local industry closing the talent gap, adopting new technologies, boosting innovation, and diversifying leadership.

“Make It Better” forecasts a high-tech future that encompasses robotics, connected computing, enhanced automation, and other applications surrounding Industry 4.0A report released last March by MAGNET revealed that Northeast Ohio is fast becoming an advanced production hub. The organization’s first Blueprint Report Card—MAKE IT HAPPEN: A Progress Report on the Blueprint for Manufacturing in Northeast Ohio—also illuminated a local industry closing the talent gap, adopting new technologies, boosting innovation, and diversifying leadership.

MAGNET board member Jack Schron believes the hype when it comes to the regional manufacturing sector. Schron, president and CEO of Cleveland tool and equipment producer

Jergens Inc., says MAGNET's new headquarters in Hough stands as a symbol of the manufacturing industry's evolution and future direction.

The 53,000-square-foot facility, opened in November 2022, hosts classrooms, a prototyping lab, a STEM-themed playground, and a technology showcase and engineering floor.

MAGNET’s sparkling HQ is also emblematic of a sector that’s far more inviting than in decades past, Schron says.

Jack Schron, president and CEO of Jergens, Inc.“[At Jergens], you’re not walking onto a shop floor, you’re entering a technical distribution center,” he explains. “You’ll see a clean, air conditioned environment where people are using robots, lasers, and other ultra-sophisticated equipment.”

Jack Schron, president and CEO of Jergens, Inc.“[At Jergens], you’re not walking onto a shop floor, you’re entering a technical distribution center,” he explains. “You’ll see a clean, air conditioned environment where people are using robots, lasers, and other ultra-sophisticated equipment.”

Outreach is a vital component in bridging a manufacturing skills gap that, if left unchecked, will result in millions of unfilled jobs within the next decade, adds Schron.

“For too long, companies were only interested in taking care of their internal needs,” Schron says. “We realized we needed to change that culture and have a network that linked all of these businesses together. MAGNET was one of the leaders in doing that.”

‘The art of possibility’

A MAGNET-led sector partnership connects Jergens with other industry stalwarts on skill development and talent attraction. Through this work, Jergens and its industry peers have hired hundreds of formerly incarcerated individuals for employment opportunities that offer pathways to career advancement.

For Northeast Ohio to be a manufacturing authority in the coming years, the region must lead with workforce and trained skills development. Schron says he advocates for welcoming other marginalized groups, including those with developmental disabilities, and offering them on-site training.

MAGNET's 53,000-square-foot facility is connecting people to training and jobsGiven the current economic uncertainty around the Trump administration’s tariff reforms, mastering automation is equally crucial for American companies aiming to keep production within the U.S.

“People can come in and run a sophisticated robotic automation cell, then continue their education at no cost,” Schron says. “And companies will get the benefit of getting someone who’s helping them grow.”

MAGNET is collaborating with 100 different nonprofits, academic institutions, and workforce incubators to prepare Northeast Ohio for the next 40 years of manufacturing. CEO Karp points to new companies that are moving into nondescript buildings around town, while empty brownfields are opportunities for further manufacturing development.

“Having more manufacturing in our cities means exposing more people to the industry,” he says. “You’ll see more enthusiasm as generational turnover takes place, and the new leadership that comes on and wants to shake things up.”

Artificial intelligence and automation will be at the forefront for the near future, Karp predicts, but what about a process to make metal printing less expensive? Or a new polymer that changes the economics of plastic manufacturing? The possibilities are endless—Karp stresses the region just needs the vision and forethought to realize it.

“We have to have companies see the art of possibility,” Karp says.